I.8.

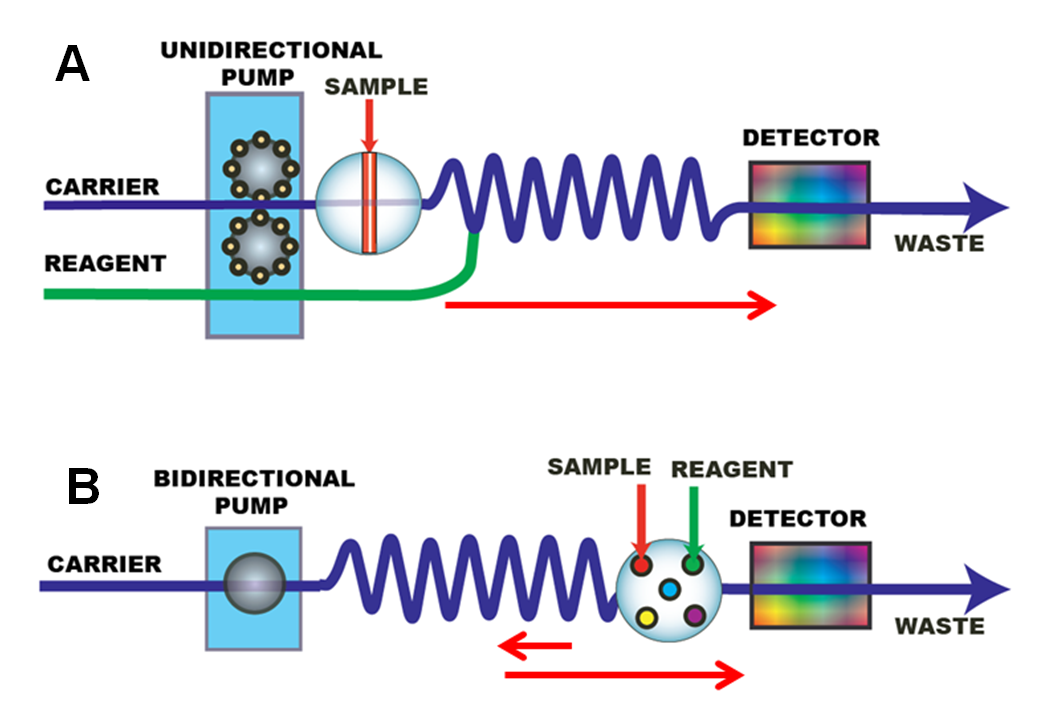

In the Flow injection system (A) sample is efficiently mixed with reagent(s) by local turbulence, which is formed during sample injection, and at confluence of merging streams. (Section 0.2.10.). Since FI operates at a continuous flow rate, the length of the incubation time, available for chemical reactions, is proportional to reactor length. Thus decreasing volume of the system , in order to reduce sample and reagent consumption, necessitates decreasing of the diameter of the channel from the usual 0.8mm, to 0.2mm or less, which creates the issues disc used in previous section. This is why there are so few references on miniaturization of FI system in Hansenís Database.

Miniaturization of Flow Analysis

Flow Injection & Sequential Injection

Sequential Injection (B) is based on flow programming, which includes stop flow periods thus making incubation time independent of the length of flow channel. The flow system is miniaturized by minimizing the length of the flow channel between the injector and detector (2.2.4.) In this so called lab-on-valve configuration the channel diameter is 0.8mm, and the sample is mixed with reagents by flow reversals (2.2.6.) Flow programming provides an unprecedented versatility, since the two principal variables, mixing of sample with reagents, and incubation, are taking place upstream from the injector, in a holding coil, where volumes and reaction times can be independently varied by the amplitude of flow reversals controlled by computer. The miniaturized version of the SIA system can be configured either as one line miniSIA-1 analyzer, or two line multipurpose miniSIA-2 analyzer (2.6.2.). Miniaturized SIA instrument has been used to automate nutrient assays at sampling rates over 100s/hr with sample and reagent consumption using decimicroliter volumes of sample and reagents (2.2.13.)